Incinerator Introduction

ZMFS is a waste incineration equipment with dependent intellectual property rights developed by Shandong ZHIMAI Environment Protection Technology Co.,Ltd, It is fully enclosed,compact in structure and highly efficient in incinerating which boasts reasonable process,leading technology,and a high degree of harmlessness.

Technical Parameter

Item

Item Model | ZMFS-30 | ZMFS-50 | ZMFS-100 | ZMFS-150 | ZMFS-300 | ZMFS-500 |

Treatment capacity | 30-50kg | 50-100kg | 100-150kg | 150-200kg | 300-400kg | 500-600kg |

Incinerator size (m) | 1.9*1.3*2.6 | 2.1*1.4*3.05 | 2.3*1.6*3.24 | 2.3*1.65*3.55 | 2.45*1.8*3.77 | 3.1*2.2*4.85 |

Waste inlet size(mm) | 390*510 | 600*750 | 600*750 | 670*870 | 800*1000 | 890*1220 |

Chimney size (mm) Outer diameter | φ273 | φ273 | φ273 | φ325 | φ425 | φ478 |

Air blower | 0.25kw | 0.25kw | 0.25kw | 0.37kw | 0.55kw | 0.55kw |

First burner | 0.12kw | 0.12kw | 0.18kw | 0.18kw | 0.25kw | 0.25kw |

Second burner | 0.18kw | 0.18kw | 0.18kw | 0.25kw | 0.37kw | 0.37kw |

Voltage | Customize voltage | |||||

Weight (kg) | 2700 | 5000 | 6100 | 7000 | 8800 | 18000 |

Incinerator's operating control use the automatic program control system, which reduce worker's work intensity. The doors of combustion chamber and cleaning room use the Cluster-Type structure. Burning down process in the stove is isolated completely with outside to form the negative pressure combustion, and prevent the possibility of secondary pollution. This has great advantage in handling dangerous infectious medical waste.

Main Feature

1. Adopting gasification incineration technology suitable for treatment of various wastes like domestic garbage,medical garbage,various kinds of paper scraps,animal carcasses etc.

2.Using gasification incineration,all kinds of garbage generated every day can be incinerated at once.

3.Making use of gasification incineration,mixed incineration,burnout treatment and other technologies to meet the national emission standards for smoke and dust,

4.Adopting fully enclosed operation to avoid secondary pollution.

5.Compact structure,small space required.

6.This series of incinerators are divided into two types by the fuel,and users can choose according to their need,diesel or gas.

7.Ash rate less than 3%.

8.2nd combustion chamber gas retention time ≥2s.

Technical Characters

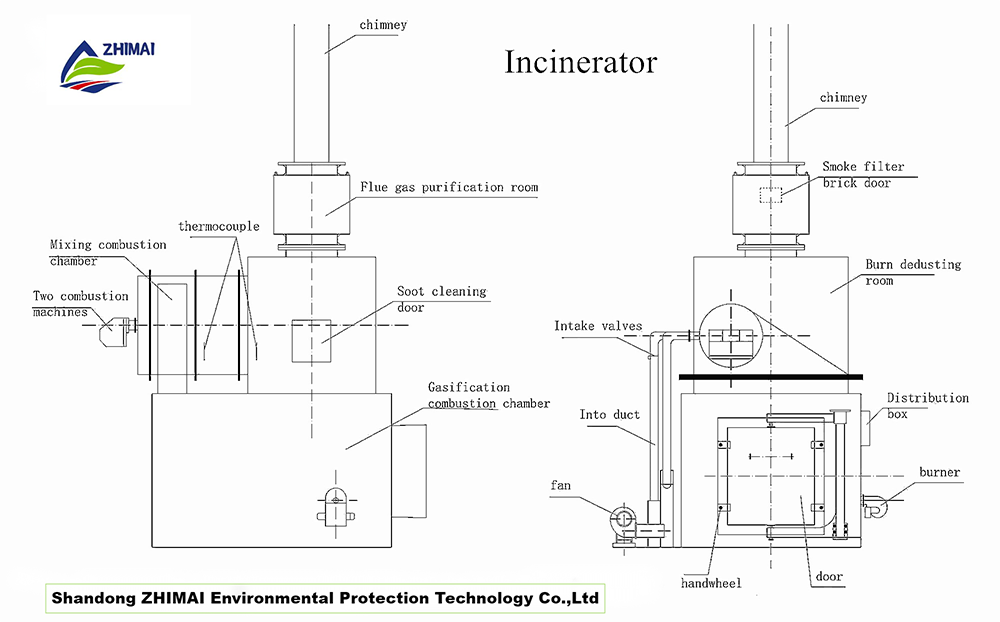

The ZMFS series of waste incinerators adopt the most advanced way of incinerating which is primary pyrolysis gasification+ surrounding air co-firing+ secondary incineration+ burnout treatment. Supported by the gasification incineration technology, the primary combustion chamber of the incinerator is designed to ensure the temperature of the incinerator in the incinerator too rise from 200ºC to 800ºC,and the garbage will not have problems such as clinker, slag and sintering during the incineration. Compares with direct combustion furnaces and other furnaces,the gasification incinerator produces a very small amount of dust. A secondary incinerator burner and a circulating air supply device are installed in the secondary mixing incineration chamber. At high temperatures,the combustible gas mixed in the flue gas can be fully burned,and the gas generated by the gasifier can be efficiently mixed with air to burn, to prevent the carbon material in the gas flame from escaping and delayed burning.When the flue gas enters the high-temperature burn-out chamber,it can be fully burned again in the burn-out chamber,and the rotary airflow is used for flue gas dust removal supported by the tangential entry and tangential entry of combustion-supporting air,etc.The residence time of the flue gas in the furnace is more than 2seconds,so that the combustible gas in the flue gas and the combustibles in the flying ash are completely incinerated.The dry exhaust gas purification equipment at the upper end is suitable for the flue gas are decomposed at high temperature.The flue gas purification system is equipment with calcium hydroxide filter bricks to neutralized the acid gas to absorb the acid gas and purify the tail gas so that harmful components in the flue gas are reduced to meet the national "Hazardous Waste Incinerator Pollution Control Standard(GB 18484-2001)"and other standards.

The operating control of the incinerator adopts automatic program control,which relieves the labor of the workers.The incinerator door and the dust-cleaning door adopts a fully sealed structure in the form of a son-mother mouth so that during the incineration,the furnace is completely isolated from the outside if the furnace,forming a negative pressure combustion which eliminates the possibility of secondary pollution,especially for the treatment of infectious hazardous medical waste,which highlight its unique advantages.

Incinerator Application

1.Animal carcass

Such as : dead animal body and pets carcasses, dog, cat, chicken,cow,pig,duck,bull,buffaloes, fish, birds, cattle, etc, farm incinerators ,

such as cattle farms, pig farms, sheep farms, stables, kennels, abattoirs, testing laboratories, catteries, pet crematoriums and poultry

farms and other waste disposals.

2.Plastic waste

(polymer waste):Plastic PE, PU, rubber (tire), Styrofoam, PET bottle, fiber, foam, cloth, bags, resin, acrylic, leather, Wood flour, urea

powder, melon cloth, tapes, paints, polymers and so on.

3.Medical waste

Hospital waste and Clinic waste,such as:bandage , swaps, injection syringe, drop bottle, lab waste, expired drugs, infectious internal organ

, napkin, diaper, mask, gloves, straps, gauze, blood vessels, organs,pharmaceutical waste, hazardous wastes , Laboratories wastes,

healthcare waste.

4.Municipal waste

Domestic daily home waste. Cardboard, paper scraps, sawdust, bottles, plastics,fruit peel, kitchen waste, papers, trash, rags, leftovers, trees,

leaves, lowers, roots, etc.

5.Industrial waste

the general waste or solid waste produced in industrial area and factories and construction sites, environmental or recycling facilities,

landfills, manufacturing, mining, agricultural eg. rubber, plastic, fiber, paper, leathers, wood, general & material , domestic wastes or from

industrial activities , solid incinerator for solid waste in factories & construction sites.

Incinerator Characteristics

1.No visible smoke,no smell,no secondary pollution.

2.Lifetime up to 8-10years.

3.Low failure rate,less maintenance and operating costs.

4.Easy to learn,easy to burn,effort-saving for everyone.

5.Negative pressure design.non-backfire,continuous feeding,and large treatment capacity.

6.High security:the open design has no risk of explosion,and has automatic water cutoff,power cutoff,and alarm safety system.

7.Secondary combustion,higher temperature treatment.