Equipment description

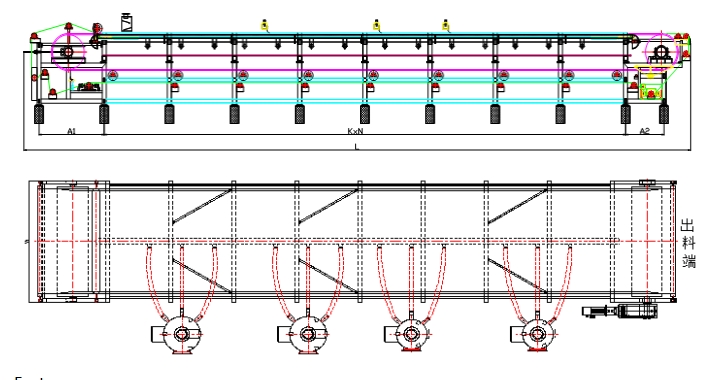

The continuous vacuum belt filter uses filter cloth as the filter medium and is an efficient separation equipment that makes full use of material gravity and vacuum suction to achieve solid-liquid separation. An integral annular rubber belt is used as the vacuum chamber. The annular tape is driven by a motor to run continuously, and the filter cloth is spread on the tape and runs synchronously. The tape contacts the annular friction belt on the vacuum slide and forms a water seal. The slurry is evenly distributed on the filter cloth by the distributor. When the vacuum chamber is connected to the vacuum system, a vacuum filtration area is formed on the tape. The filtrate passes through the filter cloth and collects through the transverse grooves on the tape and enters the vacuum chamber through the small holes. The solid particles are trapped on the filter cloth to form a filter cake.

Working principle

The working principle of the continuous belt vacuum filter is to use a vacuum pump to extract vacuum from the rotating filter cloth. The filter material is evenly added to the filter cloth and rotates with the filter cloth. The vacuum chamber of the filter at the bottom draws vacuum under the action of the vacuum pump, and the filter material is removed. The moisture of the filter material on the cloth is drained, and the dry filter material rotates with the filter cloth to the scraper, where it is scraped off by the scraper and falls directly into the transport vehicle.

Features

1. High degree of automation. Unloading, filtration, washing, slag removal, and filter cloth cleaning are all continuously automated, which improves production efficiency, reduces operating costs, greatly reduces operating costs, greatly reduces workers’ labor intensity, and improves the working environment.

2. The filtration speed is fast, the material passes through the sedimentation zone, large particles are on the bottom layer, and small particles are on the upper layer. The filter cake has a reasonable structure, and the filtrate has low resistance to penetration, allowing rapid thin-layer filtration.

3. The filtration process is convenient. The thickness of the filter cake, the amount of washing water, the number of counter current washing stages, the degree of vacuum, and the speed of the filter cloth can be adjusted arbitrarily to achieve the best filtration effect.

4. The washing effect is good; multi-stage advection or counter current washing can be realized, and the washing is even and thorough.

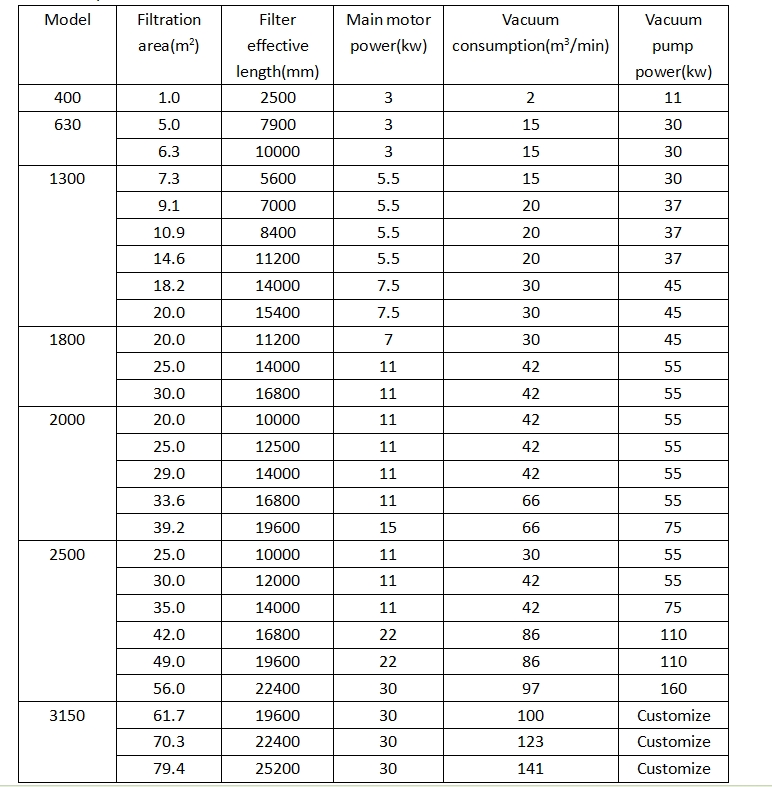

Technical parameter