Product introduction

The screw press sludge dewatering machine uses the principle of screw extrusion to squeeze and dehydrate sludge through the strong extrusion force generated by changes in screw diameter and pitch, as well as the tiny gap between the moving ring and the fixed ring. A new type of solid-liquid separation equipment.

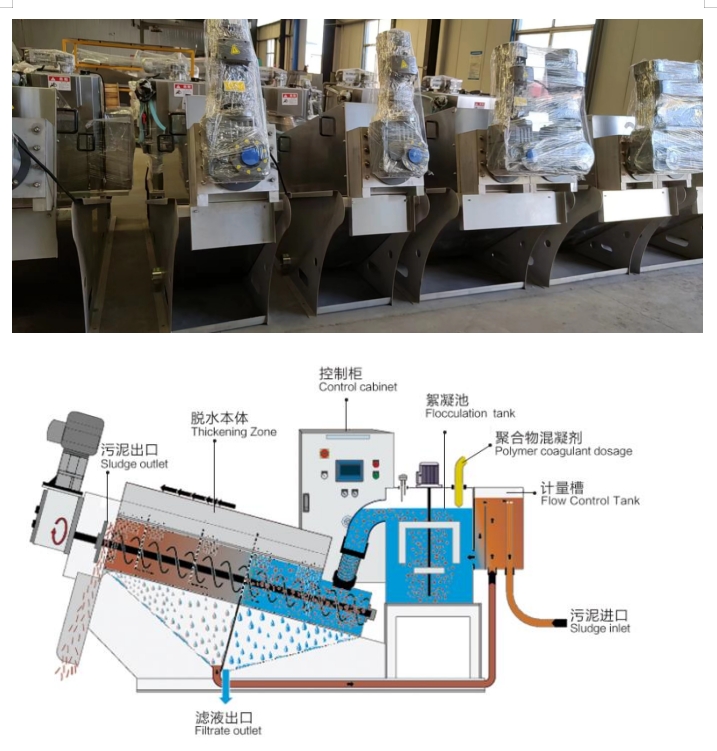

Construction principle:

The main body of the stacked snail sludge dehydrator is composed of multiple fixed rings and moving rings, and the spiral shaft runs

through it to form a filtering device. The front section is the concentration section, and the back section is the dehydration section.

The concentration, pressing and dehydration of sludge are completed in one cylinder, replacing the traditional filter cloth

and centrifugal filtration methods with a unique and subtle filter body pattern.

Dehydration principle:

After the sludge is concentrated by gravity in the concentration section, it is transported to the dehydration section. During

the advancement process, as the filter seams and pitch gradually become smaller, and under the blocking action of the back pressure plate,

a huge internal pressure is generated, and the volume continues to shrink. , to achieve the purpose of sufficient dehydration.

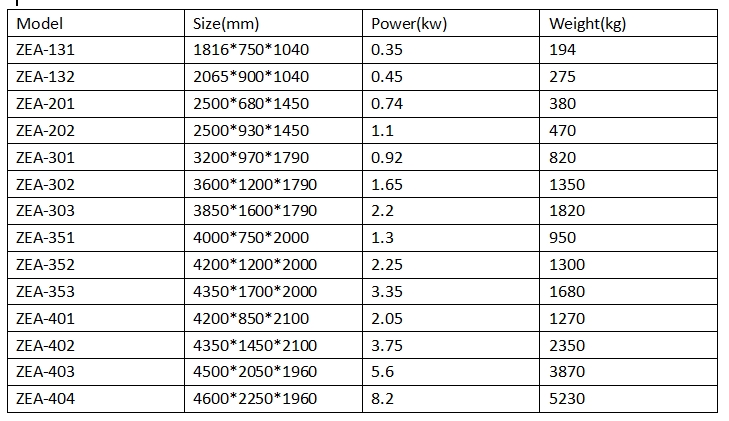

Technical parameter

Product advantages

1. Wide range of application

It can be widely used in sludge dehydration in municipal sewage, food, beverage, slaughtering and breeding, printing and dyeing,

petrochemical, papermaking, leather, pharmaceutical and other industries.

2. The equipment is not easily blocked

The dynamic and static ring filter seam structure makes the equipment less likely to be clogged. There is no need to carry out extensive

cleaning to prevent the filter seams from being clogged. This completely reduces the flushing water consumption, reduces the burden

on the internal circulation, and solves the troubles caused by the blockage of traditional dewatering equipment to enterprises.

3. Continuous automatic operation

The snail sludge dehydrator adopts automatic control from pumping out sludge, injecting liquid medicine, and discharging sludge

cake. Through the electric control cabinet, it is linked with the medicine soaking machine, mud feed pump, medicine dosing pump, etc.,

without the need for personnel to operate the equipment. , operation will not cause clogging, filter belt deviation or other phenomena

that affect process safety. Daily maintenance is simple, and it can be operated continuously unmanned 24 hours a day. The continuous

and fully automatic operation of sludge dehydration is realized.

4. Save operating costs

Integrated overall design, compact design, greatly saving operating costs. Low-speed screw extrusion technology significantly reduces

power consumption; the equipment is not clogged and flushing water is greatly reduced; 24-hour fully automatic and unmanned operation

significantly reduces labor costs.

5. No secondary pollution

The rotation speed of the spiral shaft is about 2~3 rpm, no vibration, and very little noise; its laminations have a self-cleaning function and

will not cause clogging problems. It only requires a small amount of water for flushing, and there is no secondary water pollution; plus

sludge Running in such a slow working state, the odor does not spread, thus creating a very good operating environment!

6. The body is light and durable

Since mechanical extrusion dehydration is directly used without the need for large bodies such as rollers, the machine is designed to be quite

lightweight. The body is almost entirely made of stainless steel, and the only replacement parts are the spiral shaft and the traveling ring.

It has a long service life and is durable.

7. Save project investment

The snail sludge dehydrator itself has a sludge concentration function and can directly process aerobic sludge in the aeration tank without

the need for concentration and storage units, reducing the overall space and construction costs of sewage treatment facilities.

8. Improve phosphorus removal function

When sludge is dehydrated under aerobic conditions, sludge phosphorus will not be released under anoxic or anaerobic conditions in

traditional sludge concentration tanks or storage tanks, thus improving the phosphorus removal function of the entire sewage

treatment system.