Equipment description

Micropore filtration is a method of mechanical filtration. It is suitable for separating the tiny suspended substances (pulp fibers) existing in the liquid to the maximum extent to achieve the purpose of solid and liquid separation. The difference between micro filtration and other methods is that the filter media has extremely small gaps. With the help of the centrifugal force of the screen rotation, it has a high flow rate and traps suspended solids under low hydraulic resistance.

This equipment is specially developed to address the problems that existing micro filters are prone to clogging, easy damage, heavy maintenance workload, and high secondary investment. It is one of the best practical technologies suitable for fiber recovery and wastewater treatment in wastewater.

Working principle

Micro filtration machine is a mechanical filtration device, consisting of transmission device, overflow weir water distributor, flushing water device and other main components. The filter screen is stainless steel wire mesh. Its working principle is that the treated water enters the overflow weir water distributor from the water pipe mouth. After a short period of steady flow, it overflows evenly from the water outlet and is distributed on the filter cartridge screen that rotates in the opposite direction. The water flow and the inner wall of the filter cartridge produce relative shear. Movement, high water passing efficiency, solid matter is intercepted and separated, rolls along the spiral guide plate in the barrel, and is discharged from the other end of the filter barrel. The wastewater filtered out from the filter flows away from the outlet tank directly below under the guidance of the protective covers on both sides of the filter cartridge. The machine is equipped with a flushing water pipe outside the filter cartridge. Pressurized water (3kg/cm2) is sprayed in a fan shape to clear the filter screen, ensuring that the filter screen always maintains good filtration capacity.

Features

1. Simple structure, smooth operation, easy maintenance and long life.

2. Large filtration capacity and high efficiency. Generally, the wastewater fiber recovery rate is greater than 80%.

3. Small footprint, low cost, low-speed operation, automatic protection, easy installation, water and energy saving.

4. It works fully automatically and continuously without special supervision, and the recycled fiber concentration can reach up to 12% or more.

5. By changing the filter with different meshes, it can be used instead of the concentrator and the rotary screen dehydrator.

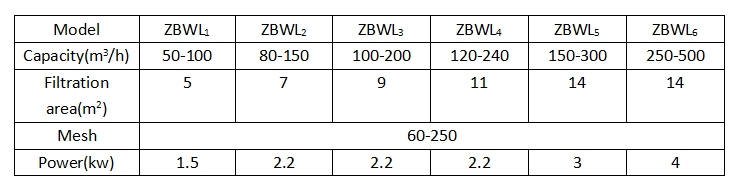

Technical parameter